Products

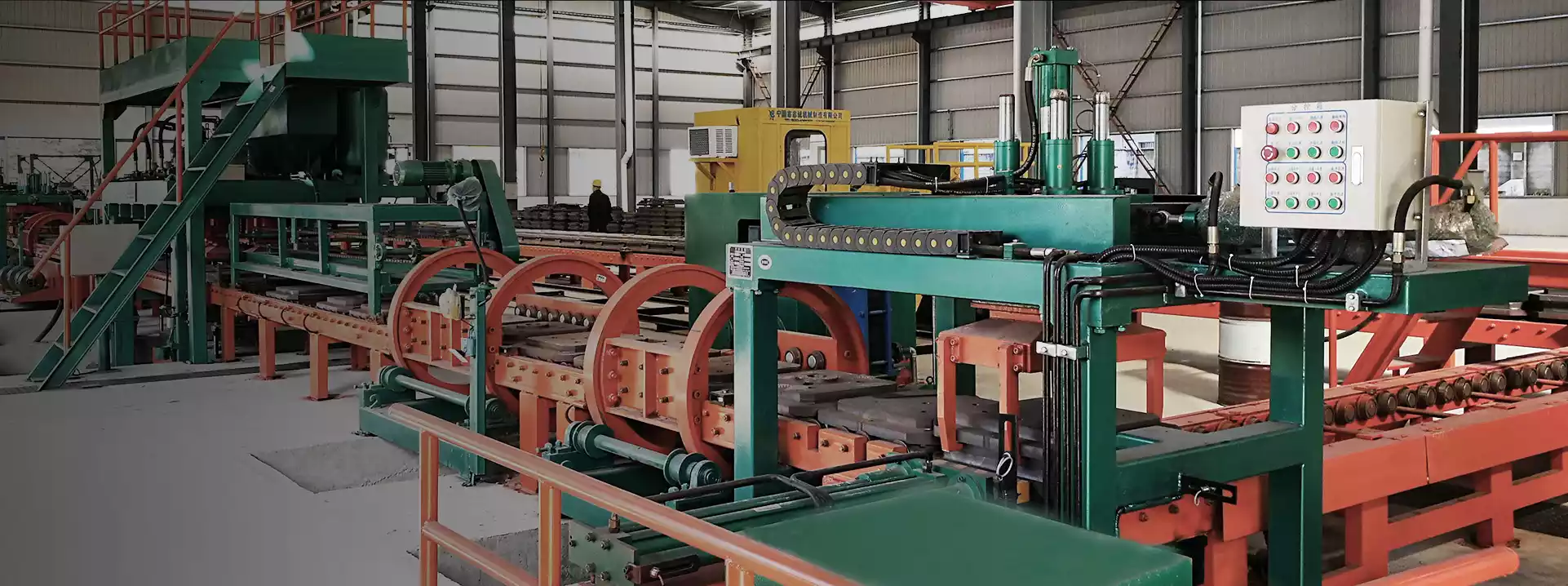

heat treatment production line

Brief Introduction

ZHICHENG series automatic push-rod type heat treatment machine (oil quench & tempering), with many years’ experience in design and manufacture of similar products, PLC intelligence control program, have the characteristics of safe and energy-saving, highly automation and high production efficiency. This equipment has multi-purpose, can be widely used in casting products, and mechanical parts of oil & air quenching, annealing, tempering etc.

With the continuous improvement of products, technical performance and degree of automation of heat treatment machines have been further improved.

Here are the main components: segmented furnace body, control cabinet, PLC cabinet, upender, shaker, shaking table, pushing device, delivery system, quench & temper baskets etc.

Working Process for Heat Treatment Machine

Quench Part: Loading grinding balls — pushing grinding balls into the furnace— preheating — heating — heat preservation —pushing balls out from the furnace — quench (oil or air) —Loading mill balls

Temper Part: Loading (original or after quenching) balls — pushing balls into temper furnace —heat —pushing balls out from furnace — Packing

Characteristics of Heat Treatment Equipment

Its advanced program can improve productivity and save energy. And compared with car-bottom heat treatment (quenching) furnace, it can save electricity 35%-50% more.

The effect of quenching is better and can stabilize; For example, in the oil quenching conditions, it can ensure the grinding ball and cylpebs’ quench uniformly.

Better to change the producing process according to the different balls heating technology.

Deal with a big ball and small ball respectively.

It can reasonably manage the equipment overhaul and maintenance.

Reduce the consumption costs of the heat-resisting steel parts.

Reduce the labor intensity and errors and easy operating.

It has multi-purpose for different castings, such as oil & water & air quenching, annealing and tempering for Hi-Cr casting, Hi-Mn castings etc.

We can CUSTOMIZE according to your REQUIREMENTS.

Product Advantage:

-

Energy saving than general heat treatment

-

Only one operator is needed.

Product detail diagram

Hot tags:

Our Services Advantage

We do not only offer excellent grinding ball making machines , but also perfect after sales-service. For machines after sales-service is very important. choosing top leader manufacturer , enjoying perfect after sales-service.

-

Inquiry Stage

-

Visit Stage

-

Production Stage

-

Delivery Stage

-

After sales-service