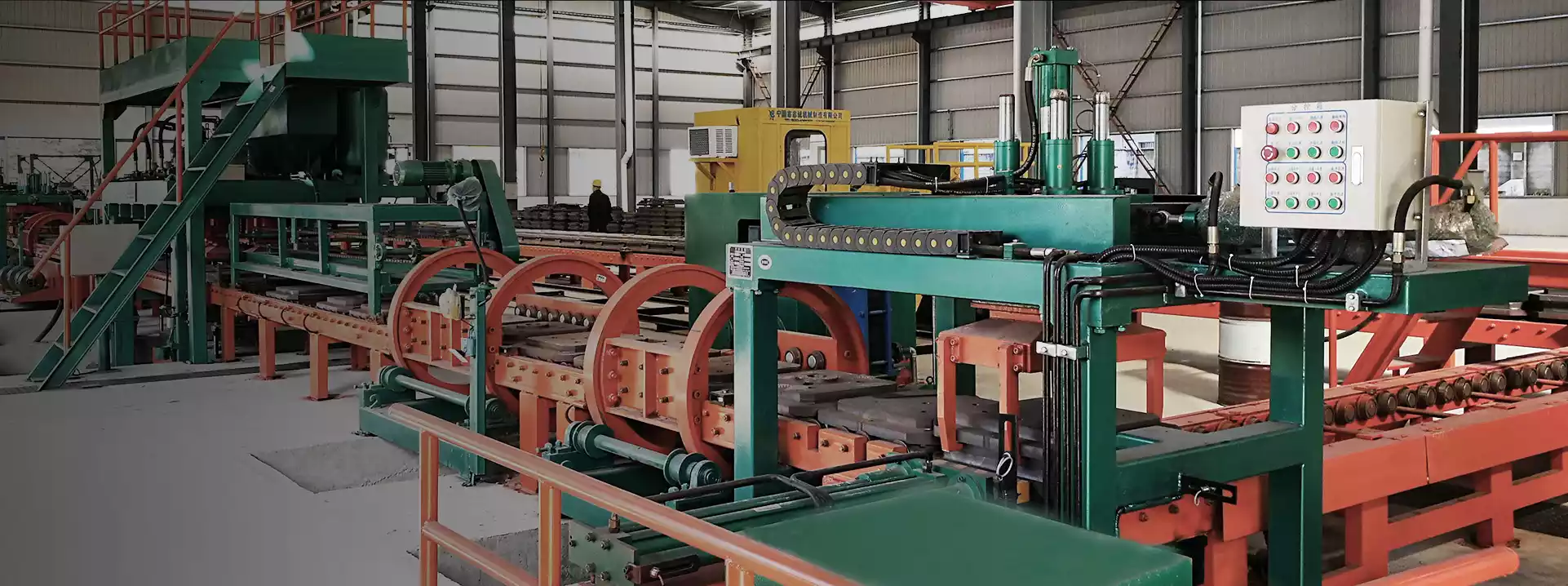

Product Description

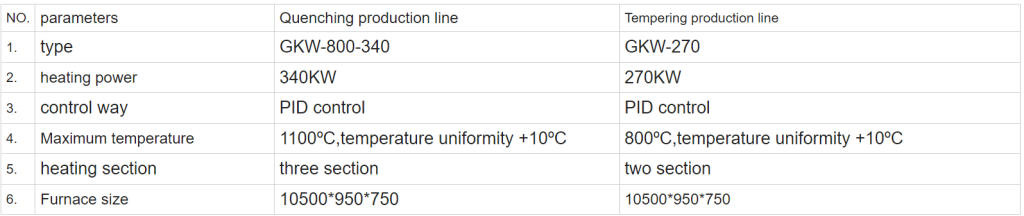

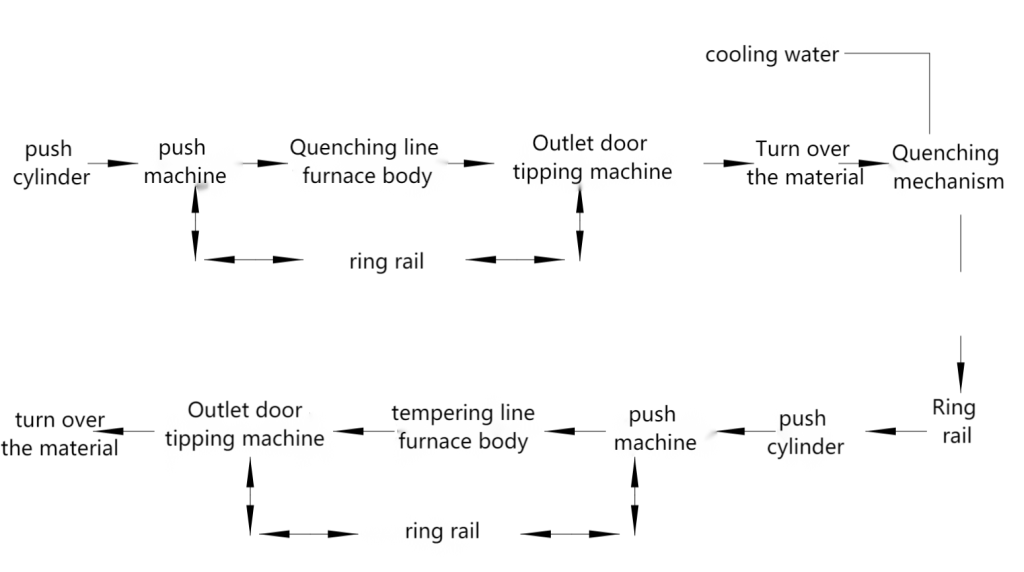

Quench Part: Loading grinding balls — pushing grinding balls into the furnace— preheating — heating — heat preservation —pushing balls out from the furnace — quench (oil or air) —Loading mill balls

Temper Part: Loading (original or after quenching) balls — pushing balls into temper furnace —heat —pushing balls out from furnace — Packing Characteristics of Heat Treatment Equipment

Competitive Advantages of Heat Treatment Production Line

1. The advanced program of automatic push-rod type heat treatment machine can improve productivity and save energy. And compared with car-bottom heat treatment (quenching) furnace, it can save electricity 35%-50% more.

2. The effect of quenching is better and can stabilize; For example, in the oil quenching conditions, it can ensure the grinding ball and cylpebs’ quench uniformly.

3. Better to change the producing process according to the different balls heating technology.

4. Deal with a big ball and small ball respectively.

5. Metal heat treatment system can reasonably manage the equipment overhaul and maintenance.

6. Reduce the consumption costs of the heat-resisting steel parts.

7. Reduce the labor intensity and errors and easy operating.

8. Automated heat treatment furnace line has multi-purpose for different castings, such as oil & water & air quenching, annealing and tempering for Hi-Cr casting, Hi-Mn castings etc. We can CUSTOMIZE according to your REQUIREMENTS.

International presence:

Zhicheng company iron mould coated sand production line has been exported to Congo, South Africa, Zimbabwe, Russia, Uzbekistan,Zambia, Vietnam, Mongolia and other countries

Certificate of honor:

Invention patent: