BASIC INFO.

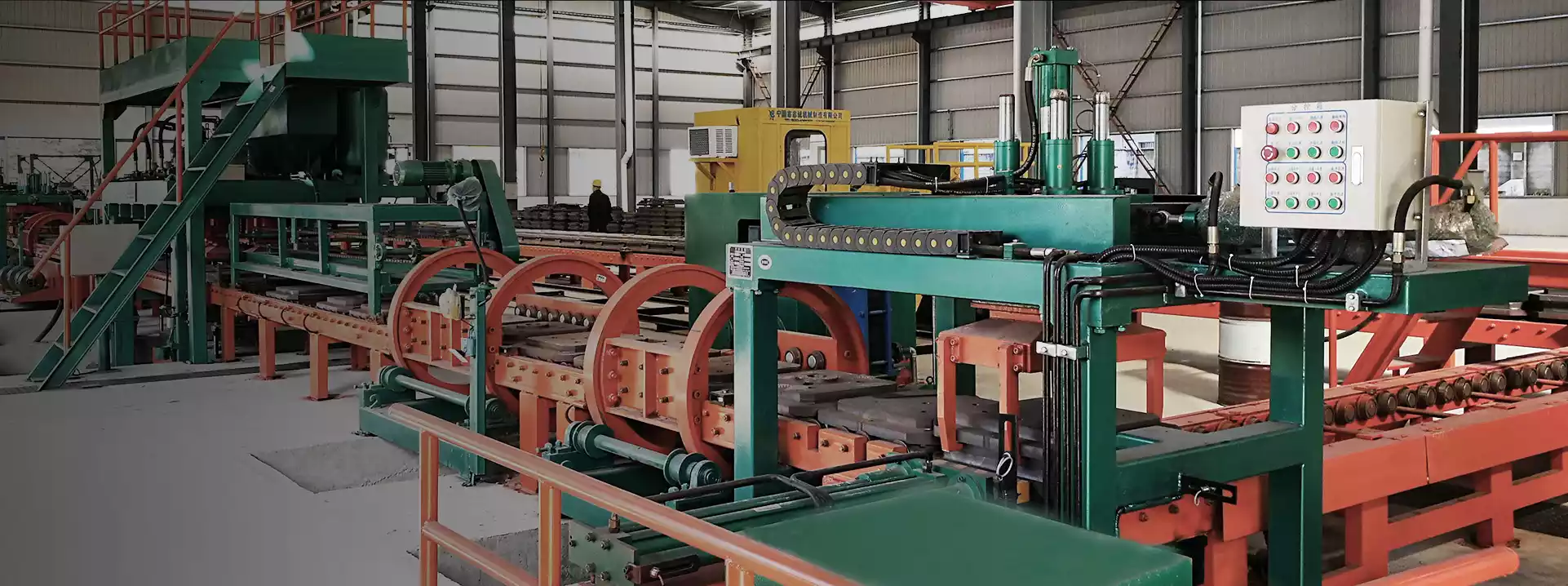

Product Description

At present, in the production, the transfer and dumping of molten iron are mostly carried out by cranes or forklifts, and there are many defects in this way: the transfer of molten iron by cranes requires workers to control the cranes, which costs more human resources; At the same time, there is a great danger in air transportation, which brings safety risks to production. The use of forklifts for transshipment also requires human resources, low stability and accuracy, and low production efficiency.

Automatic pouring machine molten iron is about to be poured when issuing a call molten iron request; After the electric furnace receives the request for calling molten metal, the operator can call the transfer car in front of the furnace and start pumping molten metal. If the furnace platform i s relatively short or tall, the cart in front of the furnace needs to have the function of lifting and lowering. According to the different parabola of the molten metal, the position of the ladle connecting to molten metal can be adjusted manually. And send it to the spheroidization station, The spheroidization station can automatically adjust the relevant parameters of spheroidization according to the sent data → the transfer car in front of the furnace automatically closes the cover after receiving the instruction to complete the discharge of hot metal → The transfer car in front of the furnace automatically runs to the position of the spheroidization station and connects with the spheroidization roller of the station → The spheroidization bag filled with hot metal is transported to the spheroidization roller The nodularization roller enters the nodularization chamber (at the same time, the change roller is connected with the transition transfer vehicle and the front transfer vehicle) → Automatically closes the door of the nodularization chamber to begin the nodularization process → the transition transfer vehicle will transport the empty nodularization package to the front transfer vehicle through the change roller table (the front transfer vehicle is ready to accept the next hot metal) → The nodularization station

door opens after the completion of the hot metal nodularization process → the nodularization roller moves out of the nodularization chamber → The nodular roller delivers the nodular package to the transition transfer vehicle → the

transition transfer vehicle runs to the slagging station after receiving the hot metal → The transition transfer vehicle rotates and then tilts (tilts to facilitate slagging) → manual slagging → After slagging is completed, the transition transfer vehicle transfers the hot metal to the position of the pouring machine → The transition transfer vehicle moves horizontally to the position of the inlet of the pouring machine. The transition transfer car goes up → The transition transfer car pourshot metal into the pouring machine → The transition transfer car returns after the completion of pouring hot metal, prepare the next package of hot metal, and cycle in turn.

International presence:

Zhicheng company iron mould coated sand production line has been exported to Congo, South Africa, Zimbabwe, Russia, Uzbekistan,Zambia, Vietnam, Mongolia and other countries

Certificate of honor Invention patent:

Invention patent: