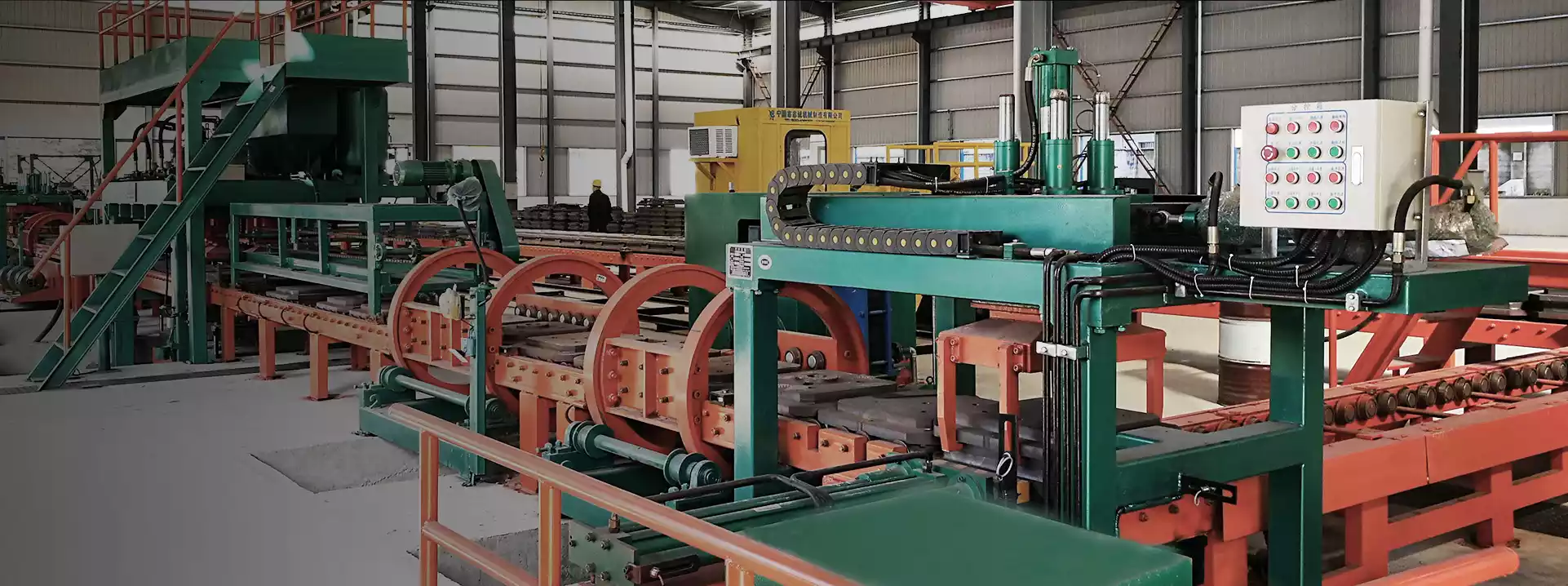

Function of Chrome Mill Ball Production Line:

Automatic grinding media ball production line adopts sand coated in metal mold cavity technology. It is used to produce casting chrome grinding media from Dia 40mm to Dia 150mm.These casting chrome grinding media is widely used in mining industry,cement plant,power plant,etc. The grinding media ball production line control mode is automatic PLC & intelligent remote service.Equipped with PLC automatic control and touching screen .Operators can monitor the whole grinding media production process by touching screen. If there is any problem,it can automatically alarm. All control box has emergency stop button.It also has the ability of remote maintenance&remote diagnose failure functions

Main Parts of Grinding Ball Casting Line:

Pouring station

Pushing grinding media mold machine

Changing direction & lifting grinding ball mold station

Motorized roller,Open mold station

Grinding ball coming out from mold station

Vibrating used sand machine

Intelligent temperature control station

Molding sand station

Close mold station

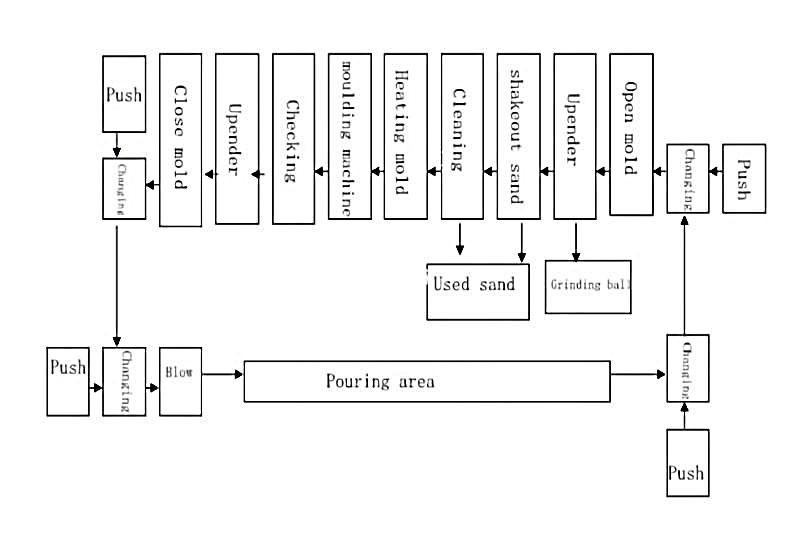

The Production Process of Grinding Media Ball Production Line :

Preheat grinding ball mold into a certain temperature-grinding ball mold into molding station and shooting sand-operatorchecks ( if the sand is not shot well into the mold cavity he operator will repair this pa ) Close mold-pouring molten metalliquid-opening mold then grinding ball coming out from the mold-cleaning the residual sand-shooting sand again.

In our factory , ZZJX-630-F4 chrome grinding media mill ball is widely sold

ZQJX-630-F4 Mill ball casting line technical parameters

| Item | ZQJX-630-F4 |

| Floor space | L37m*W12m |

| Driving mode | By hydraulic |

| Installed capacity | 100kw |

| Air Compressor | Gas consumption is 3m³/min Working pressure is 0.8Mpa |

| The fastest running speed per mold without loading | ≤40 second/mold |

| Control mode | Automatic PLC+Intelligent remote service |

| Main Workers needed | Four people |

| Grinding ball mold size | 630*630mm |

| Grinding ball mold Qty needed | 78 pairs |

The production time of mill ball automatic molding line is about 5 months

Our grinding ball molding line has exported to Congo,Zimbabwe,Outer Mongolia, Zambia,South Africa,Malawi,Vietnam,etc.

For a complete ZQJX-630-F4 grinding ball production line,it needs about 10+pcs 40 OT containers (It mainly depends on how many size mold do you need)

Our advantages:

1. We are the leading manufacturer in China for grinding media production line,grinding media heat treatment plant,grinding media mold,grinding ball producing related equipment.

2.20+Years manufacture experience.

3.We have sold out 200+Grinding ball making machines. Customers are the best way to prove the quality of our grinding ball molding lines.

4. More than40+ patent for invention

For more detail information about grinding media production line,please contact with us