BASIC INFO.

Main technical parameters:

Components and Working Principle

Pouring ladle’s tilting device, its mouse as the rotating center, to drive the molten iron directly goes into the pouring gate of the sandbox, no need to adjust the crossrange position of the ladle and its height.

The cover rotating device works as a pouring ladle tilting device, simplifying the control mechanism and can guarantee that the pouring ladle is always in a sealed state to minimize the heat dissipation of the molten iron.

After finishing pouring, the cover rotation device opens the cover, the empty ladle exits pouring machine with the help of small car delivering system and then can use the overhead crane to fill molten iron again. The base frame of a small car has the limit unit so that can ensure putting the ladle on the specific position when hanging.

The pouring ladle itself also has the titling system, when the automated pouring machine meets some problem, after exiting, can pour the molten iron back to the melting furnace.

The operation of pouring machine is at the inner side of the machine with air conditional. Operators’ sight line is very good to observe pouring situation, easy operation reduces the requirements of working stills for operators.

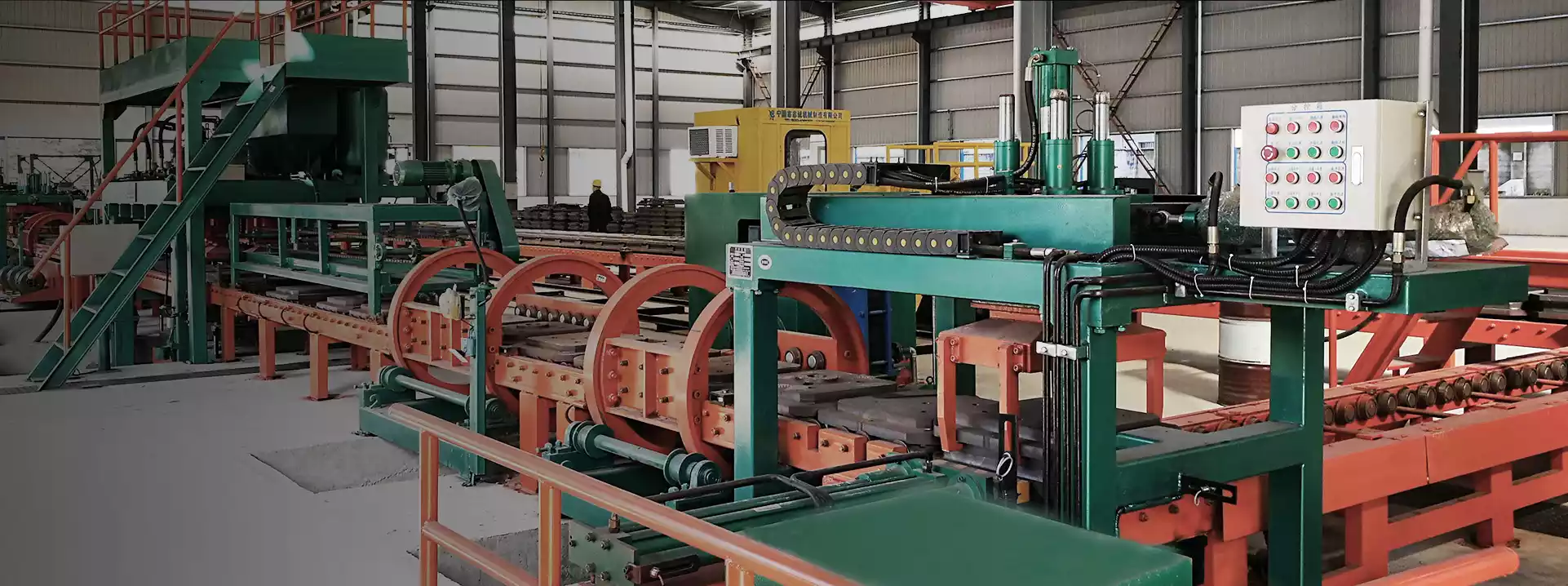

The equipment is composed of pouring locomotive body (including longitudinal drive device), tilting mechanism (including

lateral moving device), bale changing motor roller table, flow inoculation device, on-board motor roller table, pouring ladle, operation room (including electrical control cabinet and control console), etc.

International presence:

Zhicheng company iron mould coated sand production line has been exported to Congo, South Africa, Zimbabwe, Russia, Uzbekistan,Zambia, Vietnam, Mongolia and other countries

Certificate of honor

Invention patent: