Our Products

16 Years Manufaciuring Experience For Cast Grinding Ball Eouipment.

-

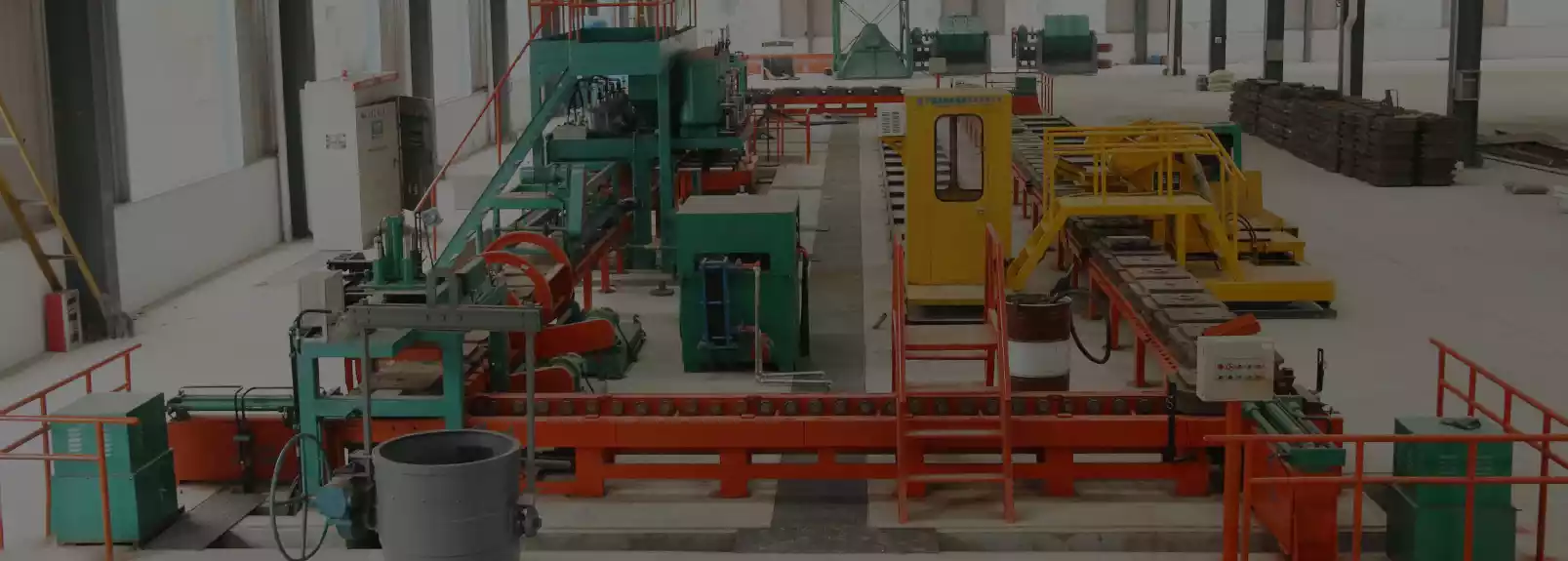

Iron mold coated sand casting production line

-

Hot metal transfer system

-

Automatic heat treatment line

-

Pouring machine

-

Grinding ball separation equipment

-

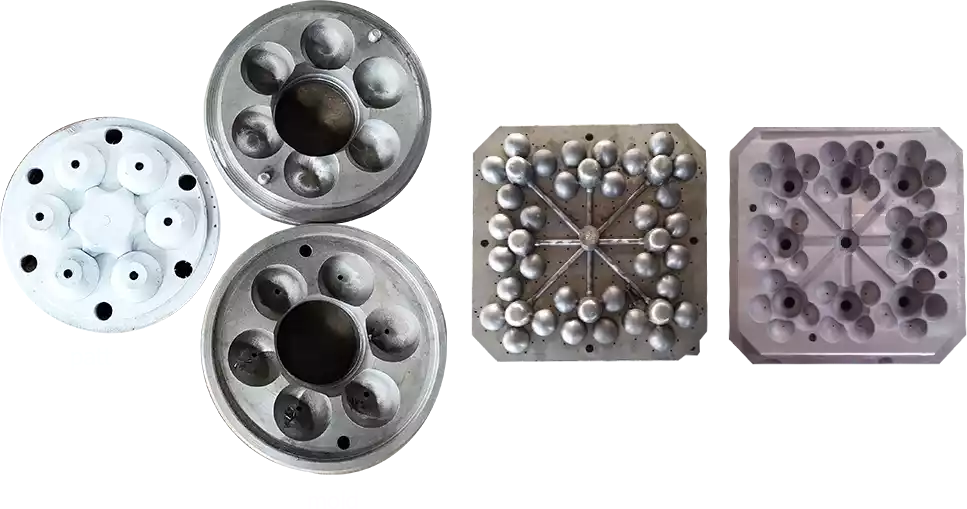

Manual metal die

Our Enterprise Advantages

Zhicheng insist on offer best service for all the foundry factory with innovation, quality and integrity.

-

Official certification

We are the only "R & D base of wear-resistant casting production equipment" designated by The Wear-resistant Casting Branch Of China Casting Association and The Technological Innovation Of China's Steel Wear-resistant Material Industry Director Unit Of Strategic Alliance And High-tech Enterprise of Anhui Province.

-

Strong R&D capabilities

We have obtained obtained 8 national invention patents and 29 utility models and presided over the formulation of the industry standard of "Iron Mold Coated Sand Molding Machine" and the local standard of "Metal Mold For Casting Grinding Ball", and formulated 9 enterprise standards.

-

Received multiple awards

The leading product of Zhicheng brand "ZZJX-F Iron mold sand covered casting production line" has been awarded "Foundry Equipment Innovation Award" by China Foundry Association for three consecutive times. "Casting ball automatic separation and sorting equipment" was recommended by China Casting Standardization Committee as the second prize of China Machinery Industry Science and Technology in 2020.

About Zhicheng Machine

Our Services Advantage

We do not only offer excellent grinding ball making machines , but also perfect after sales-service. For machines after sales-service is very important. choosing top leader manufacturer , enjoying perfect after sales-service.

-

Inquiry Stage

-

Visit Stage

-

Production Stage

-

Delivery Stage

-

After sales-service

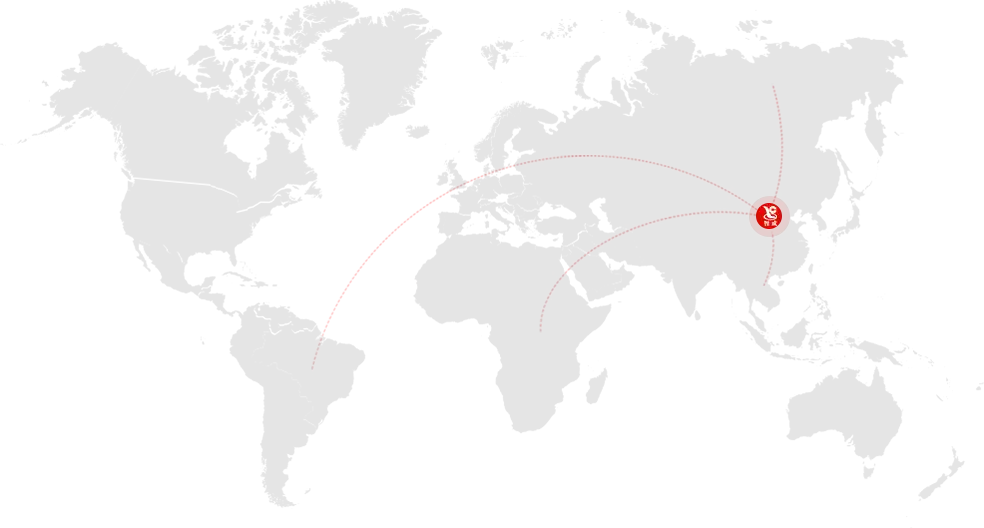

Global sales network

Our products are exported overseas and have received unanimous praise from customers

South America

Africa

Russia

Southeast Asia

News and Exhibition

Follow our latest updates to understand the trends of the enterprise.

-

Comprehensive Guide to Heat Treatment in Grinding Media Balls

Grinding media balls are an essential component in various industries, particularly in grinding mills. To enhance their performance and increase their lifespan, heat treatment plays a crucial role. In this guide, we’ll explore the signi...

2025.05.22 -

Main Working Principle of Heat Treatment Furnace: Everything You Need to Know

Heat treatment furnaces are essential tools in various industries, such as metalworking, manufacturing, and materials science. They are designed to alter the properties of materials, primarily metals, through controlled heating and cool...

2025.05.07 -

How to Choose the Best Grinding Media Balls for Your Milling Process

Introduction: Optimize Milling Efficiency with the Right Grinding Media Balls When it comes to industrial grinding, choosing the right grinding media balls is crucial for enhancing milling efficiency. Whether you are involved in mini...

2025.04.21